SERVICES

Southeast Mechanical Contractors

HVAC Services

Design Assist

Southeast Mechanical Contractors (SMC) has a long history of success on Design Assist, Design & Build and IPD (Integrated Project Delivery). SMC works quickly to take a lead role in all Design Assist efforts. We develop a working relationship with the Engineer of Record and Design Team early in the process to aid in cohesive team approach to the design. SMC helps to guide the design such that the Client is delivered a top quality installation within the agreed to HVAC Budget. We develop Value Engineering concepts to resolve issues in the most cost & quality effective way possible. SMC supports the Design Assist effort throughout the Pre-Construction phase of the project with budget updates for each revision. Our focus is delivering the Client a project that meets the Design Criteria while maintaining our initial budget all the way through to Permit Drawings. Our Operations staff then installs per the fully developed drawings eliminating Change Orders for items needed to conform to the Design Concept.

Retrofit

SMC provides replacement services for major equipment such as water cooled chillers, cooling towers, air cooled chillers, chilled water air handling units, and water source heat pumps. We replace major equipment after hours, weekends, or during other non-occupied times and have replaced an entire chiller plants in short time frames to accommodate Owner’s obligations to their Tenants.

New Construction

SMC is one of the leading Mechanical Contractors in South Florida Construction Market for Commercial, Industrial, Institutional, Educational, Healthcare, Stadium, Hospitality and Retail new construction projects. Our knowledgeable staff assists our clients in filling the design gaps and work with the Design Teams to see the design through to installation. We provide quality projects with respect to equipment, products, or materials. SMC utilizes an in-house Quality Control Program and in-house Safety Program.

SMC’s Ownership has direct involvement with the project. We always maintain or exceed the project schedule. SMC utilizes prefabrication on all projects to enhance and maintain the project schedule. Our Project Management Staff focus on cost control and management of our Subcontractors. We review all Subcontractor processes to provide a seamless Team on each project.

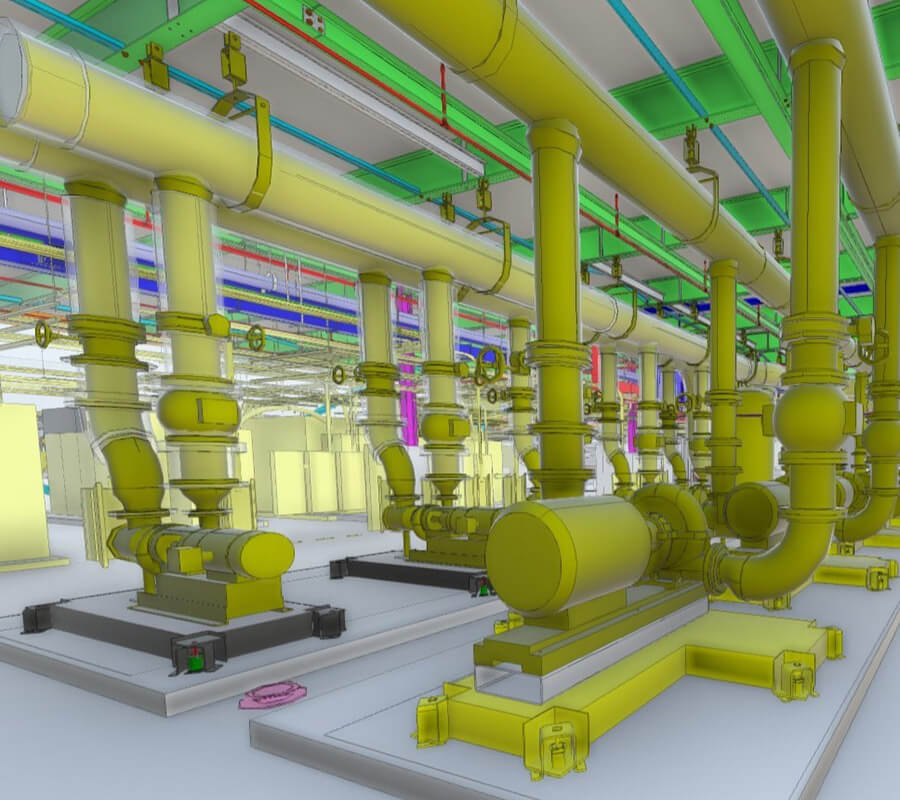

BIM – 3D Modelling and Design

SMC has (20+) years’ experience with 3D drawings. We developed 3D models prior to the advent of BIM for our use in fabrication and installation. Our transition to BIM was made easy due to our years of 3D experience, SMC has since embraced BIM coordination and we have used it successfully on numerous projects such as FAU Innovation Village, FAU Freshman Dorm, & Max Planck Research Facility.

SMC takes the lead in interdisciplinary coordination with other trades and we drive the coordination process to insure timely delivery of a fully coordinated model.

SMC takes a lead role on all projects in BIM coordination, as by the nature of our trade the duct and large diameter chilled water piping are often the largest utilities in the above ceiling/shaft spaces it is advantageous for us to not only complete our model earlier than other trades, but to also help to guide the other trades into a mutually beneficial fully coordinated model as early in the project as possible.

Prefabrication

Early coordination and fabrication assures on time delivery within the project schedule. SMC utilizes prefabricated piping fabricated at our Hollywood, FL facility to minimize field fabrication. This process provides a higher quality fabricated product while reducing overall cost. Our chiller plants are almost completely prefabricated prior to installation. The prefabricated manifolds, piping runs, and equipment connections are fabricated and labeled for installation per SMC Shop Drawings from 3D model spool sheets. The prefab is then delivered to the site to be fit, tacked in to place, and welded out using the same 3D spool sheets and SMC Shop Drawings.